Early Warning System

If a radioactive gauge is accidentally smelted in the furnace, how long will it take before the melt shop personnel realize that the smelting has occurred?

RADMELT Early Warning System (RMEWS) automates alert and shutdown processes, ensuring rapid and reliable response.

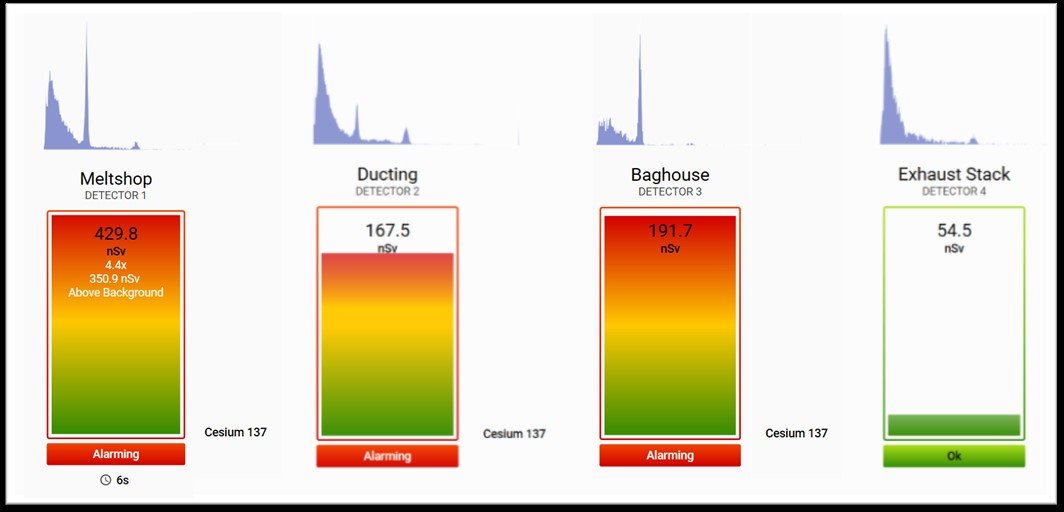

The RMEWS includes multiple RC7000 crystal detector panels strategically located in the melt shop furnace and pulpit area, along the off-gas dust collection system, and on the exhaust fume stack. The crystal-based detector panels are connected into the plant’s network, communicating with a central controller located in an area where personnel will be present during scanning periods.

During normal operation, the RMEWS passively operates, with no interference or interruption to any of the plants operation. Once there is a radiation melt situation which needs to be addressed, the RMEWS will immediately notify local personnel and prompt PLC plant control systems to trigger appropriate alerts and procedures.

The RMEWS is capable of performing a number of different rad-melt simulations and can easily be configured to accommodate each steel plant’s unique mode of operation.

Request for quote

The RMEWS interface provides real-time detector operational information, allowing personnel to view the system performance at a glance. During normal operation, the RMEWS passively operates with no interference or interruption to any of the plant’s operations. Once there is a radiation melt situation which needs to be addressed, the RMEWS system will immediately notify local personnel and prompt the plant control system to trigger the appropriate alerts and step-by-step procedures.

The RMEWS system stores raw data before, during and after the smelting of a radioactive source, allowing the user to replay the entire event as it unfolded, at a time-selected-at-a-glance view and/or selected and controlled replay speed.